I started this thread because there's lot of controversy of what's actually happening between Stylus an Vinyl while playing a record.

The reason not to see it as just a simple gliding process is because the friction coefficient between Diamond and Steel with 0.1 is roughly three lower as the 0.3 between Diamond and Vinyl.

This 0.3 seems rather accurate as measured by Pardee, see attachment 2

Despite the much lower friction, a stainless steel LP proves to be almost unplayable and shows large abrasion damage to Diamond and LP after playing it just once.

So, this posting is a search for the reason, why a vinyl LP can be played over and over with only very minor wear to both LP and Stylus.

I would like to start with a copy of an email I received from Dagfinn with definitions as a reaction to our earlier discussions, it's helpful as a starter for the discussion. In this discussion reference is made to Bastiaans, see attachment 1.

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

Bastiaans states in the intro: "At high bearing loads complete plastic flow sets in and the needle leaves a permanent indentation track, while at lower loads the elastic deformation is predominant."

From Bastiaans: An important detail is that the "slight permanent indentation" seen is made using a spherical stylus with a relatively small contact patch, which applies a much more concentrated force than a line contact stylus like Shibata.

The Shibata was developed just because of the wear observed from elliptical styli when developing CD4, in the years just before 1970. In order for an elliptical to track CD4 45khz, exceedingly high VTF was needed, and wear was too high. Shibata improved that a lot, and today several line contacts have equal or even greater contact patch compared to Shibata.

A MicroLine tracking at 2g, for instance. It's contact patch is much larger, as is the radius of the same patch. (Or even at lower VTF, like T4P standard 1,25g.)

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

Conclusions

The main question at the start of this thread was: why is a steel LP unplayable, causing great damage to LP and tip after just one time playing and why is Vinyl so much better suited as information carrier .

Permanent deformation

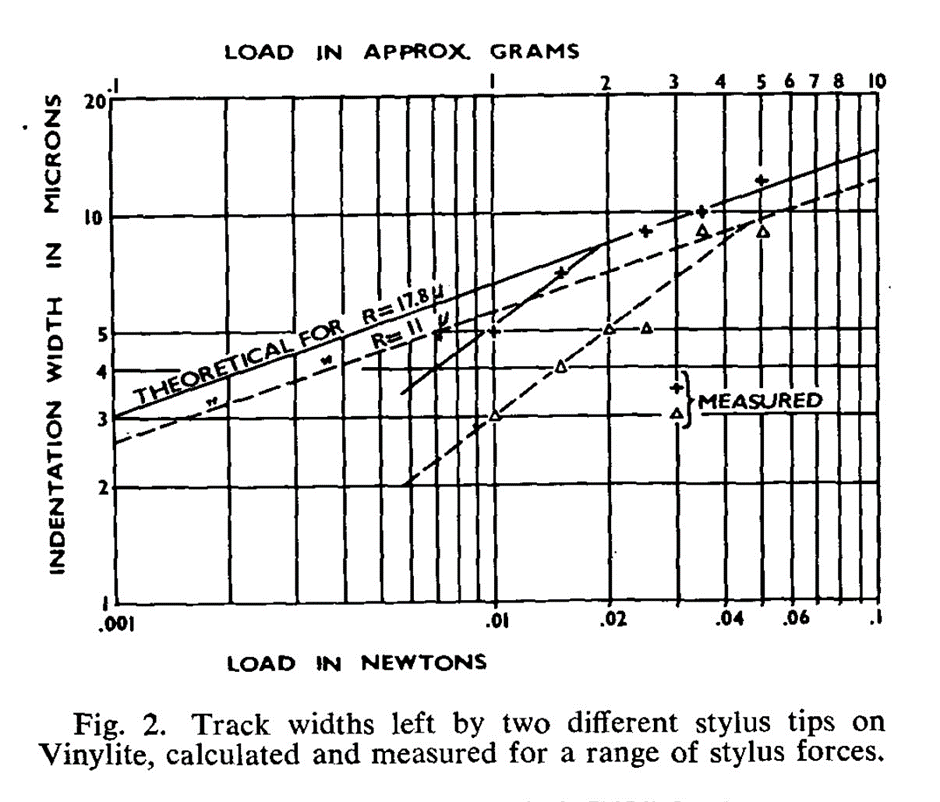

Bastiaans applied a very thin soap film to the groove wall, played a record and inspected after playing the wideness of the trace where because of permanent deformation caused by plastic flow the soap was scraped from the groove wall. With a 17.8u and a 11u round tip, above 2gram stylus force, theory and practice where perfectly in line and confirming the indentation., a formidable mathematic prestation.

Below 2 gram stylus force the deformation slope did suddenly deviate from the prediction maybe because of a surfboard effect according to a suggestion from Walton.

With a 17.8u diamond and 2 g force, stylus pressure becomes 4.8e4 psi, where the yield point of vinyl is 1.4e4 psi, so permanent deformation because of entering the plastic state was to be expected.

With a Shibata or Line Contact Stylus, the pressure or force per square inch becomes much smaller, so most likely with these more modern styli, deformation will be much less with 2 gram force.

Mis-tracking

The earlier mentioned effect of mis-tracking, or stylus loosing contact with the groove, will be followed by a hard landing back into the groove.

According to F=m*a, the pressure on the vinyl because of the huge acceleration force may exceed the vinyl’s yield point, resulting in permanent deformation.

An excellent example is given in the photographic image below, taken with a Keyence VHX-7000 microscope, from a brand new LP played after multiple playings with a Grado Cart with a tracking force of 1.5gram. Stylus shape unknown, but looking at the indent’s shape, most likely a round tip.

The LP in question was Pink Floyd's Time from Dark Side of the Moon

Permanent damage caused by mistracking

Temp rise from pressure versus rotational friction .

Some documents are mentioning that, under the stylus pressure, the Vinyl is melting, almost giving the impression that the free air melting point is reached.

Between 70C and 80C, PVC starts evaporate chlorine and at 215C PVC really melts.

Using P*V=R*T should help to prove this huge temp rise. However the Boyle / Gay-Lussac law only applies to gasses and is not of any use in this case.

That under enough pressure the elastic state above the Yield point may turn into its plastic state is true, but this not the same as melting. Compare it to overstretching material that doesn’t turn back into its original position. In this case the tip force of a few gram makes the PVC hardly rises in temp as can be measured on the Diamond tip having a very high heat conductivity, however attempt to measure a temp rise in static position showed results smaller as the equipment’s accuracy.

With a coefficient of friction of 0.3 and a stylus weight set at 2gram or 20mN, force to drag the stylus through the groove is 6mN.

When moving on the LP’s outer groove, speed is 0.55m/sec, resulting in 3.3mWatt turned into heat.

The only halfway reliable tip temp measurement I know of is from van den Hull with 60C, so a 35Kelvin temp rise above room temp.

But others like George came with much lower measured results.

Higher than 60C seems very unlikely because playing at 78rpm would increase the 3.3mW into 7.8mW and accordingly resulting in a ca 107C tip temp.

This could permanently damage the vinyl (or shellac) which does not happen, so even 60C may be questionable.

But still assuming the 60C tip temp as being correct, a large 3u*10u contact surface to conduct as much heat away from the tip and a penetration depth of 10u into the vinyl and using a heat transfer ratio k for Vinyl of 0.15, results according to k*(contact area)/(penetration depth) into 0.45uW/K.

The heat energy transferred from a +35Kelvin heated tip to the Vinyl becomes 35*0.45=16uWatt.

Again back to the outer track that moves with 55cm/sec.

In one second the PVC volume being heated is in 55cm*10u line contact*10u penetration depth is 5.5e-5 cm3 and with a specific PVC weight of 1.4 gives 77.7e-5 gram PVC material.

Specific heat for PVC is 0,9J/(gram*Kelvin)

Applying the earlier calculated 16uWatt for one second equates to 16uJ, and with the 7.7e-5 gram this results in a temp rise for the groove of 0.23Kelvin.

Play a bit with penetration dept and line contact area, and it becomes clear that because of friction temp rise of the groove wall will in all cases stay below a few Kelvin.

Static versus Dynamic pressure

Bastiaans measured on a straight groove, where in real life the tip undergoes huge acceleration forces.

A 0.5mg stylus, being exposed to 2.000m/s^2 will see a force of 1 mN according to F=m*a, to be combined in some way with 19.6 mN (or 2gram) tracking force, so that's seemingly not playing a big role. Static pressure seems to be dominating as long as the stylus faithfully follows the groove.

Hans

The reason not to see it as just a simple gliding process is because the friction coefficient between Diamond and Steel with 0.1 is roughly three lower as the 0.3 between Diamond and Vinyl.

This 0.3 seems rather accurate as measured by Pardee, see attachment 2

Despite the much lower friction, a stainless steel LP proves to be almost unplayable and shows large abrasion damage to Diamond and LP after playing it just once.

So, this posting is a search for the reason, why a vinyl LP can be played over and over with only very minor wear to both LP and Stylus.

I would like to start with a copy of an email I received from Dagfinn with definitions as a reaction to our earlier discussions, it's helpful as a starter for the discussion. In this discussion reference is made to Bastiaans, see attachment 1.

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

Bastiaans states in the intro: "At high bearing loads complete plastic flow sets in and the needle leaves a permanent indentation track, while at lower loads the elastic deformation is predominant."

- Understanding "elastic" as defined by https://www.britannica.com/science/elasticity-physics "elasticity, ability of a deformed material body to return to its original shape and size when the forces causing the deformation are removed."

- Plastic: "plasticity, ability of certain solids to flow or to change shape permanently when subjected to stresses of intermediate magnitude between those producing temporary deformation, or elastic behavior, and those causing failure of the material, or rupture (see yield point)." https://www.britannica.com/science/plasticity

- Yield point: "yield point, in mechanical engineering, load at which a solid material that is being stretched begins to flow, or change shape permanently, divided by its original cross-sectional area; or the amount of stress in a solid at the onset of permanent deformation. The yield point, alternatively called the elastic limit, marks the end of elastic behavior and the beginning of plastic behaviour." https://www.britannica.com/science/yield-point

- Deformation and flow: "deformation and flow, in physics, alteration in shape or size of a body under the influence of mechanical forces. Flow is a change in deformation that continues as long as the force is applied." https://www.britannica.com/science/deformation-mechanics

From Bastiaans: An important detail is that the "slight permanent indentation" seen is made using a spherical stylus with a relatively small contact patch, which applies a much more concentrated force than a line contact stylus like Shibata.

The Shibata was developed just because of the wear observed from elliptical styli when developing CD4, in the years just before 1970. In order for an elliptical to track CD4 45khz, exceedingly high VTF was needed, and wear was too high. Shibata improved that a lot, and today several line contacts have equal or even greater contact patch compared to Shibata.

A MicroLine tracking at 2g, for instance. It's contact patch is much larger, as is the radius of the same patch. (Or even at lower VTF, like T4P standard 1,25g.)

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

Conclusions

The main question at the start of this thread was: why is a steel LP unplayable, causing great damage to LP and tip after just one time playing and why is Vinyl so much better suited as information carrier .

- I was hoping on a Skating on Ice similarity, where a thin layer of very low friction “slurry” is formed under pressure. However no further evidence is found to support this for a Diamond tip riding on Vinyl.

- That plastic melts into a fluid under the tip pressure as propagated by some can be completely rejected.

- Temp rise of the Vinyl groove because of static stylus force and dynamic friction while playing, will not exceed at the most a few degrees, where the friction component is dominant.

See below “Temp rise from pressure versus rotational friction”. - As long as the stylus is faithfully following the track, static pressure on the groove wall is far greater than the additional dynamic pressure while playing despite huge acceleration.

See below “Static versus Dynamic pressure”. - However, when the stylus is temporarily mis-tracking because of very high modulation because of a stylus force that´s too low or wrong anti skating setting, the stylus will be catapulted into the air and when landing back into the groove it may exceed the yield point, leading to permanent deformation.

See below: “Mis-tracking”. - The only plausible explanation for the difference between Steel and PVC as the LP’s information carrier may be because of their Young’s modulus that’s 100 times larger for steel as for Vinyl.

Compare both materials for wheels under a car.

Rubber (read Vinyl) with a high elasticity, rides comfortably. Even low profile tires (read Shellac) are still doing an acceptable job, but changing the tires for steel versions will make the care undrivable, with great damage to the steel tires and the road.

Downside however is, the more flexible the groove wand, the more the deviation from the envisaged groove track, leading to distortion of the audio signal.

LAST with their preservative to treat the Vinyl just once, claims extended LP life and IMD figures that may be 10dB lower as without, so does it increase the PVC’s Young´s modulus in combination with a more slippery surface?

Unfortunately I couldn’t find any tests confirming this.

But as Pardee has measured, the coefficient of friction can indeed be lowered from 0.3 to almost 0.1 with certain preservatives.

That’s why I have planned to do the IMD and the Pardee friction test in the time to come.

Permanent deformation

Bastiaans applied a very thin soap film to the groove wall, played a record and inspected after playing the wideness of the trace where because of permanent deformation caused by plastic flow the soap was scraped from the groove wall. With a 17.8u and a 11u round tip, above 2gram stylus force, theory and practice where perfectly in line and confirming the indentation., a formidable mathematic prestation.

Below 2 gram stylus force the deformation slope did suddenly deviate from the prediction maybe because of a surfboard effect according to a suggestion from Walton.

With a 17.8u diamond and 2 g force, stylus pressure becomes 4.8e4 psi, where the yield point of vinyl is 1.4e4 psi, so permanent deformation because of entering the plastic state was to be expected.

With a Shibata or Line Contact Stylus, the pressure or force per square inch becomes much smaller, so most likely with these more modern styli, deformation will be much less with 2 gram force.

Mis-tracking

The earlier mentioned effect of mis-tracking, or stylus loosing contact with the groove, will be followed by a hard landing back into the groove.

According to F=m*a, the pressure on the vinyl because of the huge acceleration force may exceed the vinyl’s yield point, resulting in permanent deformation.

An excellent example is given in the photographic image below, taken with a Keyence VHX-7000 microscope, from a brand new LP played after multiple playings with a Grado Cart with a tracking force of 1.5gram. Stylus shape unknown, but looking at the indent’s shape, most likely a round tip.

The LP in question was Pink Floyd's Time from Dark Side of the Moon

Permanent damage caused by mistracking

Temp rise from pressure versus rotational friction .

Some documents are mentioning that, under the stylus pressure, the Vinyl is melting, almost giving the impression that the free air melting point is reached.

Between 70C and 80C, PVC starts evaporate chlorine and at 215C PVC really melts.

Using P*V=R*T should help to prove this huge temp rise. However the Boyle / Gay-Lussac law only applies to gasses and is not of any use in this case.

That under enough pressure the elastic state above the Yield point may turn into its plastic state is true, but this not the same as melting. Compare it to overstretching material that doesn’t turn back into its original position. In this case the tip force of a few gram makes the PVC hardly rises in temp as can be measured on the Diamond tip having a very high heat conductivity, however attempt to measure a temp rise in static position showed results smaller as the equipment’s accuracy.

With a coefficient of friction of 0.3 and a stylus weight set at 2gram or 20mN, force to drag the stylus through the groove is 6mN.

When moving on the LP’s outer groove, speed is 0.55m/sec, resulting in 3.3mWatt turned into heat.

The only halfway reliable tip temp measurement I know of is from van den Hull with 60C, so a 35Kelvin temp rise above room temp.

But others like George came with much lower measured results.

Higher than 60C seems very unlikely because playing at 78rpm would increase the 3.3mW into 7.8mW and accordingly resulting in a ca 107C tip temp.

This could permanently damage the vinyl (or shellac) which does not happen, so even 60C may be questionable.

But still assuming the 60C tip temp as being correct, a large 3u*10u contact surface to conduct as much heat away from the tip and a penetration depth of 10u into the vinyl and using a heat transfer ratio k for Vinyl of 0.15, results according to k*(contact area)/(penetration depth) into 0.45uW/K.

The heat energy transferred from a +35Kelvin heated tip to the Vinyl becomes 35*0.45=16uWatt.

Again back to the outer track that moves with 55cm/sec.

In one second the PVC volume being heated is in 55cm*10u line contact*10u penetration depth is 5.5e-5 cm3 and with a specific PVC weight of 1.4 gives 77.7e-5 gram PVC material.

Specific heat for PVC is 0,9J/(gram*Kelvin)

Applying the earlier calculated 16uWatt for one second equates to 16uJ, and with the 7.7e-5 gram this results in a temp rise for the groove of 0.23Kelvin.

Play a bit with penetration dept and line contact area, and it becomes clear that because of friction temp rise of the groove wall will in all cases stay below a few Kelvin.

Static versus Dynamic pressure

Bastiaans measured on a straight groove, where in real life the tip undergoes huge acceleration forces.

A 0.5mg stylus, being exposed to 2.000m/s^2 will see a force of 1 mN according to F=m*a, to be combined in some way with 19.6 mN (or 2gram) tracking force, so that's seemingly not playing a big role. Static pressure seems to be dominating as long as the stylus faithfully follows the groove.

Hans

Attachments

Last edited:

"Lubricants

Lubricants are added to the resin mix to improve the flow of the resin during processing and aid in the release from the stampers. These lubricants are sometimes referred to as ‘mold-release agents. They are typically hard natural waxes like Carnauba or Montan or synthetic waxes like Stearamide or distearyl amide. This lubricant also aids in reducing friction, heating, and wear at the contact points of the stylus and hence helps to reduce surface noise."

From: Composition of Vinyl Records

Lubricants are added to the resin mix to improve the flow of the resin during processing and aid in the release from the stampers. These lubricants are sometimes referred to as ‘mold-release agents. They are typically hard natural waxes like Carnauba or Montan or synthetic waxes like Stearamide or distearyl amide. This lubricant also aids in reducing friction, heating, and wear at the contact points of the stylus and hence helps to reduce surface noise."

From: Composition of Vinyl Records

Where would that leave shellac and 78s? You can play those using a modern arm and an appropriate stylus. Shellac is nowhere near as elastic as vinyl...could it be the elasticity index, where steel is much harder and doesn't flex at all under these conditions ?

Hi Steven, good point, shellac probably not even having a lubricating surface.

So what the cause of the difference with steel may be, is still unclear.

Hans

P.s. We once had an airplane company in Holland called Fokker, with a commercial director called Steven Crook.

He introduced himself with;

Hello I’m Steven Crook from Fukker.

So what the cause of the difference with steel may be, is still unclear.

Hans

P.s. We once had an airplane company in Holland called Fokker, with a commercial director called Steven Crook.

He introduced himself with;

Hello I’m Steven Crook from Fukker.

Last edited:

Thx for the link."Lubricants

Lubricants are added to the resin mix to improve the flow of the resin during processing and aid in the release from the stampers. These lubricants are sometimes referred to as ‘mold-release agents. They are typically hard natural waxes like Carnauba or Montan or synthetic waxes like Stearamide or distearyl amide. This lubricant also aids in reducing friction, heating, and wear at the contact points of the stylus and hence helps to reduce surface noise."

From: Composition of Vinyl Records

The aliance is even coming to Haarlem in september, 40km from where I live.

Could this be a place to find some answers ?

Hans

I'm not sure I can agree with either the idea that friction is a significant contributor, compared to contact pressure, or that contact pressure is so dominated by static loading ("tracking force"), although dynamic forces must remain below static to maintain tracking.

G. Alexandrovich (of Fairchild, Stanton Magnetics, and AES governor) in G. Ballou (editor) Handbook for Sound Engineers 1st edition pp. 888-889 :

"Because of the small area of contact that exists between the stylus tip and the groove, the pressure against the groove wall can rise up to many thousands of pounds per square inch. For instance, if each wall receives 0.7 g of force applied through the contact area equal to 2/10 millionths of an inch (0.2 x 10 exp-6), the pressure is 7726 lb/sq in. It has been experimentally shown that with such high pressures and force of friction between the stylus and the vinyl, that the outer skin layer of the record material melts as the tip slides over the plastic and then refreezes almost as fast as it melted. It has been suggested that since the melting temperature of the vinyl is about 480F that the same temperature exists in the contact area. If the record material is metal, which happens when metal mothers are played, then the pressure increases to 20,000 to 30,000 lb/sg in, and the temperature can reach 2000F because there is no plastic deformation of the groove wall. This explains why styli made out of diamond, which is nothing more than carbon, literally burn up or wear out in a couple of hours when they are used to play metal mothers. If liquids are used to cool the contact area, then the diamond wear diminishes drastically, but the metal surface of the record is burnished. If the liquid is applied to the vinyl surface, then the temperature of the plastic surface cannot increase and melt; therefore, the scouring of the groove wall can be observed, as shown in Fig 23-118."

This seems a fair summary of the Received Wisdom in the 1970s. I suspect our intuition fails us at such small dimensions and huge deforming pressures.

All good fortune,

Chris

G. Alexandrovich (of Fairchild, Stanton Magnetics, and AES governor) in G. Ballou (editor) Handbook for Sound Engineers 1st edition pp. 888-889 :

"Because of the small area of contact that exists between the stylus tip and the groove, the pressure against the groove wall can rise up to many thousands of pounds per square inch. For instance, if each wall receives 0.7 g of force applied through the contact area equal to 2/10 millionths of an inch (0.2 x 10 exp-6), the pressure is 7726 lb/sq in. It has been experimentally shown that with such high pressures and force of friction between the stylus and the vinyl, that the outer skin layer of the record material melts as the tip slides over the plastic and then refreezes almost as fast as it melted. It has been suggested that since the melting temperature of the vinyl is about 480F that the same temperature exists in the contact area. If the record material is metal, which happens when metal mothers are played, then the pressure increases to 20,000 to 30,000 lb/sg in, and the temperature can reach 2000F because there is no plastic deformation of the groove wall. This explains why styli made out of diamond, which is nothing more than carbon, literally burn up or wear out in a couple of hours when they are used to play metal mothers. If liquids are used to cool the contact area, then the diamond wear diminishes drastically, but the metal surface of the record is burnished. If the liquid is applied to the vinyl surface, then the temperature of the plastic surface cannot increase and melt; therefore, the scouring of the groove wall can be observed, as shown in Fig 23-118."

This seems a fair summary of the Received Wisdom in the 1970s. I suspect our intuition fails us at such small dimensions and huge deforming pressures.

All good fortune,

Chris

Bastians, who has proven to be a knowledgeable calculator, calculated that with a 17.8u diamond, pressure with 2g stylus force is 4.8e4 psi, where the yield point of vinyl is 1.4e4 psi.

So in that case, vinyl exceeds its yield point and turns into a plastic state.

And turning into its plastic state under pressure does not mean like heating to anything up to 480F.

The diamond tip with very good heat conductivity would burn the epoxy binding to the cantilever and separate.

But for as far as I know, there are no measurements known showing extreme temp rise of the diamond stylus.

So, here I come (again) with my skating comparison.

When skating, you don't skate on ice but on a lubricating film in between.

Weight of the skater is by far not enough to reach the yield point where ice can be turned into water.

However, studies are showing that under pressure the crystalline molecule structure on the surface breaks down into a semisolid, forming a lubrication film.

The moment the pressure is relieved, the lubrication film turns back into ice.

Alighiszem provided a link to an article in the New York Times, where they called this "lubricating ice-rich slurries at discontinuous high-pressure zones"

So far so good, the above suggesting that a solid crystalline substance has a state in between before turning into a fluid, a plastic crystal state, nothing having to do with Plastic or Vinyl.

true crystal → plastic crystal → true liquid.

The energy needed to form this slurrie is is consumed again after relief of pressure.

Did you ever see steam coming from the ice after a skater has passed, no of course not, neither do the temp of your skate blades rise.

PVC has an amorphous structure and doesn't have this plastic crystal state in between like ice has.

However I'm happy with the link that Alighiszem provided, telling that 20% of the LP compound has a crystalline structure.

This is the compound with the properties that Ice has, let's say being able to form the the same lubricating slurrie under a pressure much lower as the yield point.

This could be the answer to the problem.

Hans

So in that case, vinyl exceeds its yield point and turns into a plastic state.

And turning into its plastic state under pressure does not mean like heating to anything up to 480F.

The diamond tip with very good heat conductivity would burn the epoxy binding to the cantilever and separate.

But for as far as I know, there are no measurements known showing extreme temp rise of the diamond stylus.

So, here I come (again) with my skating comparison.

When skating, you don't skate on ice but on a lubricating film in between.

Weight of the skater is by far not enough to reach the yield point where ice can be turned into water.

However, studies are showing that under pressure the crystalline molecule structure on the surface breaks down into a semisolid, forming a lubrication film.

The moment the pressure is relieved, the lubrication film turns back into ice.

Alighiszem provided a link to an article in the New York Times, where they called this "lubricating ice-rich slurries at discontinuous high-pressure zones"

So far so good, the above suggesting that a solid crystalline substance has a state in between before turning into a fluid, a plastic crystal state, nothing having to do with Plastic or Vinyl.

true crystal → plastic crystal → true liquid.

The energy needed to form this slurrie is is consumed again after relief of pressure.

Did you ever see steam coming from the ice after a skater has passed, no of course not, neither do the temp of your skate blades rise.

PVC has an amorphous structure and doesn't have this plastic crystal state in between like ice has.

However I'm happy with the link that Alighiszem provided, telling that 20% of the LP compound has a crystalline structure.

This is the compound with the properties that Ice has, let's say being able to form the the same lubricating slurrie under a pressure much lower as the yield point.

This could be the answer to the problem.

Hans

I'll scan the photo of 100 wet plays of a vinyl record, where heating isn't allowed, and post it here tomorrow. The damage is quite dramatic, and the explanation that melting isn't allowed in wet play seems reasonable. (Fig 23-118 mentioned above).

The issue of friction is more difficult. Because diamond's thermal conductivity is much better than that of vinyl we might expect heating from friction to be greater in the diamond than in the vinyl surface. But I'm not convinced that friction is nearly as significant for our purposes as pressure, whose effect is essentially all in the vinyl.

Still wary of analogies on our human scale.

Much thanks, and all good fortune,

Chris

The issue of friction is more difficult. Because diamond's thermal conductivity is much better than that of vinyl we might expect heating from friction to be greater in the diamond than in the vinyl surface. But I'm not convinced that friction is nearly as significant for our purposes as pressure, whose effect is essentially all in the vinyl.

Still wary of analogies on our human scale.

Much thanks, and all good fortune,

Chris

Hi,could it be the elasticity index, where steel is much harder and doesn't flex at all under these conditions ?

Sorry for intruding (I always enjoy reading your posts even if sometimes I only understand a small percentage of them).

I'm not an engineer (although I would have liked to be and illo tempore I enrolled at the Polytechnic University of my city, but only for the first two preparatory years), but isn't steel a more elastic material than rubber and therefore probably also than vinyl?

Edit: an unpretentious post, just out of curiosity...

Hi Ulogon

Thx for your friendly words and all contributions are welcome.

The Young modulus for steel a is about 100 times larger as for plastic.

I would say the less force you need to extend rods with the same length and diameter, the more elastic the material is. With plastic you will need 100 times less force.

So it’s comparable to steel wheels versus rubber wheels under your car.

One is driveable, the other is certainly not.

Does this apply to a vinyl LP also?

It’s hard to find the Young modulus for shellac used to make LP’s, but what I found varies from 3 tp 5 times larger as vinyl but still a far cry from steel.

Hans

Thx for your friendly words and all contributions are welcome.

The Young modulus for steel a is about 100 times larger as for plastic.

I would say the less force you need to extend rods with the same length and diameter, the more elastic the material is. With plastic you will need 100 times less force.

So it’s comparable to steel wheels versus rubber wheels under your car.

One is driveable, the other is certainly not.

Does this apply to a vinyl LP also?

It’s hard to find the Young modulus for shellac used to make LP’s, but what I found varies from 3 tp 5 times larger as vinyl but still a far cry from steel.

Hans

There's a similar (off-)topic currently in this thread: https://www.diyaudio.com/community/...transfer-functions.397815/page-4#post-7428362

One thing I will say is that since vinyl deforms the contact area will increase lowering the contact pressure probably below any risk of permanent deformation, certaintly I don't think there's the slightest chance of melting (see the micrographs in the other thread). On these physically small scales heat escapes very rapidly as its a diffusion thing, twice the size is four times as slow, so half the size is four times quicker, and you've diamond on one side, the ultimate heatsink. The stylus is only moving at low speed (0.5m/s or so?), probably the drag force is a fraction of a gram, so friction power might be a few mW, which is very easy to dissipate from something 10's of microns across.

Anyone have any idea whether cavitation in wet playing could be a thing? That would be bad, but the speeds just seem glacial for this sort of energetic damage.

One thing I will say is that since vinyl deforms the contact area will increase lowering the contact pressure probably below any risk of permanent deformation, certaintly I don't think there's the slightest chance of melting (see the micrographs in the other thread). On these physically small scales heat escapes very rapidly as its a diffusion thing, twice the size is four times as slow, so half the size is four times quicker, and you've diamond on one side, the ultimate heatsink. The stylus is only moving at low speed (0.5m/s or so?), probably the drag force is a fraction of a gram, so friction power might be a few mW, which is very easy to dissipate from something 10's of microns across.

Anyone have any idea whether cavitation in wet playing could be a thing? That would be bad, but the speeds just seem glacial for this sort of energetic damage.

Last edited:

Hi Mark,

In your link you mention that vinyl is nowhere near its melting point because of the pressure applied unlike ice while skating.

Truth is exactly the opposite. What Bastians has shown for a round tip, is that for this tip the yield point is exeeded and plastic state will be entered, but for skating on ice this is not the case.

The other thing is seeing the tip as a heatsink.

Very little energy would be needed to make the tip very hot. However the pressure is not heating the tip, it is just indenting the Vinyl and in case it exceeds the yield point plastic flow sets in.

The real heat is caused by friction when the LP turns, but this heat is consumed by the vinyl at the same time preventing the tip from getting hot.

Hans

In your link you mention that vinyl is nowhere near its melting point because of the pressure applied unlike ice while skating.

Truth is exactly the opposite. What Bastians has shown for a round tip, is that for this tip the yield point is exeeded and plastic state will be entered, but for skating on ice this is not the case.

The other thing is seeing the tip as a heatsink.

Very little energy would be needed to make the tip very hot. However the pressure is not heating the tip, it is just indenting the Vinyl and in case it exceeds the yield point plastic flow sets in.

The real heat is caused by friction when the LP turns, but this heat is consumed by the vinyl at the same time preventing the tip from getting hot.

Hans

Isn't the technology there (things like a thermal microscope) to measure all this and keep speculation and argument out of it? Maybe expensive to do properly and there's no monetary return for doing it?

The thermal microscopy linked above - I wondered about setting it up to look at a stylus in a locked track.

It's an interesting subject , you know, the usual wonder of a tiny pointy thing wiggling a magnet . . . . . . . amazing really. As for the physics of contact , I'm just thinking, if the effects and causes are debateable then more data is required. That's all.

It's an interesting subject , you know, the usual wonder of a tiny pointy thing wiggling a magnet . . . . . . . amazing really. As for the physics of contact , I'm just thinking, if the effects and causes are debateable then more data is required. That's all.

And this may be getting at the source of some skepticism about vinyl melting. We tend to think of temperature on our human scale, as something added to a physical thing, maybe by friction or maybe by contact with something already at higher temperature, and not as something that arises as a result of PV=RT or external pressure to any body. Pressure causes temperature to rise, and deformation is proof of the pressure.The real heat is caused by friction when the LP turns, but this heat is consumed by the vinyl at the same time preventing the tip from getting hot.

The counter example of wet play shows what happens when melting isn't allowed, and the counter example of playing metal shows what happens when deformation isn't allowed.

All good fortune,

Chris

Early in this discussion, it was mentioned that a line stylus, taking up a smaller footprint would also decrease heat? Wouldn't it be just the opposite? Pounds per square inch.

In an extreme example, the stylus is equal to a metal rod that you are grinding at the grinding wheel, where as the rod gets much hotter than the moving wheel. The difference though is that the grinding wheel is much harder than the steel rod that it is grinding. Maybe like the idea of using the metal stamped record to play. There are more variables than I expected with this observation.

In an extreme example, the stylus is equal to a metal rod that you are grinding at the grinding wheel, where as the rod gets much hotter than the moving wheel. The difference though is that the grinding wheel is much harder than the steel rod that it is grinding. Maybe like the idea of using the metal stamped record to play. There are more variables than I expected with this observation.

A line contact stylus has a larger footprint in the sense of area of vinyl impacted than earlier profiles. They originated when folk were trying to find a way to play CD4 records, which need to be able to trace the small wavelengths of up to 45KHz subcarrier. Simply making an elliptical stylus smaller would allow it to fit into the smaller wiggles but increased pressure so much that record damage was too swift. A larger footprint was also needed to move the stylus effective tip mass (mass to be moved by the groove walls) x vinyl compliance resonance as high as possible, by reducing vinyl effective compliance (same force over larger area).

Vinyl playback is so interesting partly because it's like a bumblebee - can't possibly fly, but it does. If Edison had been able to do a 1970s engineering analysis he might not have bothered. Arf!

All good fortune,

Chris

Vinyl playback is so interesting partly because it's like a bumblebee - can't possibly fly, but it does. If Edison had been able to do a 1970s engineering analysis he might not have bothered. Arf!

All good fortune,

Chris

And the microscope is expensive. Not to mention the problems in doing this with a moving target where the object of interest is stupidly small, buried in a groove and operating at tolerances that mean the act of measuring might affect results.there's no monetary return for doing it?

I wonder if this would actually make an interesting grad student project in an engineering department somewhere....

- Home

- Source & Line

- Analogue Source

- Effect of Stylus friction on LP