I recently was offered 8K Toshiba 2SK170 and 4K 2SJ74. The deal was for genuine parts subject to testing. We don’t really need them but I can’t say no to fets.

Six genuine Toshiba boxes showed up with sealed bags. The 2SK170‘s date codes matched the boxes and were the real deal.

The J74’s had dc parameters not matching genuine parts and the date codes didn’t match the box. Internally the lead frames matched but the die didn’t. The broker took the J74 parts back, they mostly deal in digital parts and couldn’t test them.

Plenty of fakes out there.

Six genuine Toshiba boxes showed up with sealed bags. The 2SK170‘s date codes matched the boxes and were the real deal.

The J74’s had dc parameters not matching genuine parts and the date codes didn’t match the box. Internally the lead frames matched but the die didn’t. The broker took the J74 parts back, they mostly deal in digital parts and couldn’t test them.

Plenty of fakes out there.

Attachments

awesome on that linear devices lsk..

why don't the manufacturers do more of these? I dont really know the intricacies of semi fab, but it cant be like setting up a factory for a car model. some section/lab in some facility, they get the photolitho plates, the chemicals, etc, (assuming all the supplies are there what, a day or two to set up?). begin production of a little range of the most desired extinct discretes, make a few giant cases full (they don't go bad if stored properly right?) and sell them. if someone can enlighten me on the theoreticals on time/number of people/prohibited chemicals; how many sold to break even (although I imagine it as a "look, we're a great company" loss leader *actually, having looked at the LSK for $14 each on digi, they're not going poor selling them ).

I mean, SONY restarted vinyl record production again. china knocks off all non Chinese products- in the semiconductor case here they cant, they just create a non-working forgery.

real manufacturers can go "hey, since we love you wealthy, influential Americans, we will make these available through X distributors or direct- in quantities 5, 10,15 of (no buying a case then send them to china (which doesn't make sense. why would they buy at retail what they only want to resell) or resell on ebay). we support America, diy, right to repair (no user serviceable parts sticker sill in force on our money making things, like flat-screen televisions lol)

Oh, related- does anyone still make vacuum tubes, besides the mystery black hole that is the shenzen industrial area (or wherever. a china joke)?

I remember that after the VW beetle stopped production, they sent the tooling to brazil. then south africa. then to india. new old beetles are probably still being made somewhere. with duller and duller dies. maybe the khyber pass gunsmiths can sharpen them up.

why don't the manufacturers do more of these? I dont really know the intricacies of semi fab, but it cant be like setting up a factory for a car model. some section/lab in some facility, they get the photolitho plates, the chemicals, etc, (assuming all the supplies are there what, a day or two to set up?). begin production of a little range of the most desired extinct discretes, make a few giant cases full (they don't go bad if stored properly right?) and sell them. if someone can enlighten me on the theoreticals on time/number of people/prohibited chemicals; how many sold to break even (although I imagine it as a "look, we're a great company" loss leader *actually, having looked at the LSK for $14 each on digi, they're not going poor selling them ).

I mean, SONY restarted vinyl record production again. china knocks off all non Chinese products- in the semiconductor case here they cant, they just create a non-working forgery.

real manufacturers can go "hey, since we love you wealthy, influential Americans, we will make these available through X distributors or direct- in quantities 5, 10,15 of (no buying a case then send them to china (which doesn't make sense. why would they buy at retail what they only want to resell) or resell on ebay). we support America, diy, right to repair (no user serviceable parts sticker sill in force on our money making things, like flat-screen televisions lol)

Oh, related- does anyone still make vacuum tubes, besides the mystery black hole that is the shenzen industrial area (or wherever. a china joke)?

I remember that after the VW beetle stopped production, they sent the tooling to brazil. then south africa. then to india. new old beetles are probably still being made somewhere. with duller and duller dies. maybe the khyber pass gunsmiths can sharpen them up.

No. It's not as easy as you think. Toshiba setup a production line - and then invested lots of time and rejected parts to get the ion beam implantation just right, and then the lot testing just right. Once the equipment on the line is shut down, or repurposed to produce a different process - they'd have to go back to Square One. I think this is why Linear has had a bitch of time with yields on the J74 and other p-Channel parts. People are now asking the same question about Legacy CCD Camera sensors. They want the old sensors back. Producing CCDs is NOT anything like producing CMOS sensors. Entirely different equipment and line process is needed. It would be cost prohibitive to spin up a new CCD production line....

Agreed. The book « Only the Paranoid survive. Lessons from the CEO of INTEL Corporation » gives insight into how very small manufacturing tweaks can allow or prevent manufacture of certain integrated circuits. For years Intel was the only company able to manufacture a certain type of circuits by virtue of a temperature « ripple » that they accidentally discovered and guarded as top secret. I think even they did not understand why this temperature trick worked. Competitors had no way of guessing it. I am not saying this is the case for J74 (I am not in the know), just that there can be more than meet the eyes in the finicky IC fabrication business.

Bump...

I have two sets of supposed 2SK170BLs, one of which was purchased by Siemens when I worked there in early 2000. Normally we purchased parts directly from the warehouse at the manufacturing site for the product in development. Only when a component was not already set up did we buy from distribution such as Digi-Key, Mouser, Allied, etc. I got the parts when there was a scrap sale including bins of engineering samples that were no longer needed. The second set I purchased years ago (Forgot when) most likely from Ebay.

The latest set have the laser marked information with the straight leg on the "7".

Sorry for the poor picture quality.

The oldest set from Siemens have silkscreened markings with the curved "7"

I have two sets of supposed 2SK170BLs, one of which was purchased by Siemens when I worked there in early 2000. Normally we purchased parts directly from the warehouse at the manufacturing site for the product in development. Only when a component was not already set up did we buy from distribution such as Digi-Key, Mouser, Allied, etc. I got the parts when there was a scrap sale including bins of engineering samples that were no longer needed. The second set I purchased years ago (Forgot when) most likely from Ebay.

The latest set have the laser marked information with the straight leg on the "7".

Sorry for the poor picture quality.

The oldest set from Siemens have silkscreened markings with the curved "7"

Attachments

Last edited:

So I ran the test with a 100R resistor in the drain with a 50mV AC input to the gate, +/-10V supplies, measured the output voltage at the drain and calculated Yfs as well as measuring Idss.

For the most recent parts with the laser mark and straight "7" I got:

ID(mA) Yfs (mS)

8.65 19.8

8.96 18.4

9.12 20

8.7 18.4

8.68 18.0

9.15 18.0

9.06 19.2

9.0 18.0

9.44 18.0

9.19 19.2

For the most recent parts with the laser mark and straight "7" I got:

ID(mA) Yfs (mS)

8.65 19.8

8.96 18.4

9.12 20

8.7 18.4

8.68 18.0

9.15 18.0

9.06 19.2

9.0 18.0

9.44 18.0

9.19 19.2

... that it''s a "scrap sale": they realized the marking is wrong and trashed some perfectly good items. They should be V, or, better still, no classification because V is for 10-20mA, and most of them are outside this range.

I volunteer to relieve you of this junk and give them a proper disposal

I volunteer to relieve you of this junk and give them a proper disposal

Thank you Zung for your kind offer to dispose of them.

We (Industrial Controls Division) would get a design project from upper management (Germany) We would design the product, and have Germany build prototypes and eventually released product after agency certification and compliance testing. Along with the prototypes we would order spare parts for testing and repair from Germany if they were in the system, if not we would purchase from distribution and send some parts to production for prototypes (until they bought directly from the component manufacturer).

When a project was complete, there would be leftover parts which were not needed. Once every couple of years we would clean out the engineering lab and bins of parts would be sold internally to employees (along with obsolete laptops, computers, monitors, yada,yada,yada). This was scrap material, hence a scrap sale. Prototype modules were not included in this as they were collected and sent to e-waste for disposal.

The first parts are within the range of Idss and Yfs for a 2SK170 BL, however they are still suspect based on the time purchased (within the last 5 - 10 years). The only way to confirm would be to test them for noise floor. I may try building a test set for that.

The second parts are interesting. Even though the Idss is well above the "V" range someone sold them through a major USA electronics distributor. I have seen mention of LSK170s with Idss so high above the expected range. Maybe these are early remarked LSK170s?

We (Industrial Controls Division) would get a design project from upper management (Germany) We would design the product, and have Germany build prototypes and eventually released product after agency certification and compliance testing. Along with the prototypes we would order spare parts for testing and repair from Germany if they were in the system, if not we would purchase from distribution and send some parts to production for prototypes (until they bought directly from the component manufacturer).

When a project was complete, there would be leftover parts which were not needed. Once every couple of years we would clean out the engineering lab and bins of parts would be sold internally to employees (along with obsolete laptops, computers, monitors, yada,yada,yada). This was scrap material, hence a scrap sale. Prototype modules were not included in this as they were collected and sent to e-waste for disposal.

The first parts are within the range of Idss and Yfs for a 2SK170 BL, however they are still suspect based on the time purchased (within the last 5 - 10 years). The only way to confirm would be to test them for noise floor. I may try building a test set for that.

The second parts are interesting. Even though the Idss is well above the "V" range someone sold them through a major USA electronics distributor. I have seen mention of LSK170s with Idss so high above the expected range. Maybe these are early remarked LSK170s?

Aha, but bribery is so wrong.

Fortunately for me I am using them in part of an anode load in a tube circuit and low noise isn't critical.

I will be using them between 4 and 20mA, so the newer ones should work fine up to about 6mA. The older ones should be fine up to 20mA.

Fortunately for me I am using them in part of an anode load in a tube circuit and low noise isn't critical.

I will be using them between 4 and 20mA, so the newer ones should work fine up to about 6mA. The older ones should be fine up to 20mA.

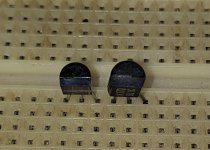

Left is the newest part which seems to be within spec, both electrically and physical dimensions. Right is the older part with high Idss and Yfs and slightly larger than spec.

Also the circular indention on the back rounded surface is clean with no markings inside the circular depression.

Also the circular indention on the back rounded surface is clean with no markings inside the circular depression.

Attachments

For me the right one looks more like the right one. The left one looks like a J11x. They also have a circular ditch on the rear. But from what I can see I wouldn't bet on the right as well, because the top of mine, which I have bought 15 years ago, do look different. If interested, I'll show a pic tomorrow. Cheers.

- Home

- Amplifiers

- Pass Labs

- Replacement For Toshiba 2SK170/2SJ74