What is the best internal lining for sealed and ducted boxes?

Do sealed boxes really need internal lining?

I once made a sealed box and covered it with glass wool but I was never able to check whether or not it made a difference to the sound.

For ducted boxes with subwoofers intended for deep bass, what coating should I use?

Do sealed boxes really need internal lining?

I once made a sealed box and covered it with glass wool but I was never able to check whether or not it made a difference to the sound.

For ducted boxes with subwoofers intended for deep bass, what coating should I use?

Generally speaking:

A sealed box would be loosely filled with absorbent material such as carded sheeps wool: https://www.woollyshepherd.co.uk/loudspeaker-wool/

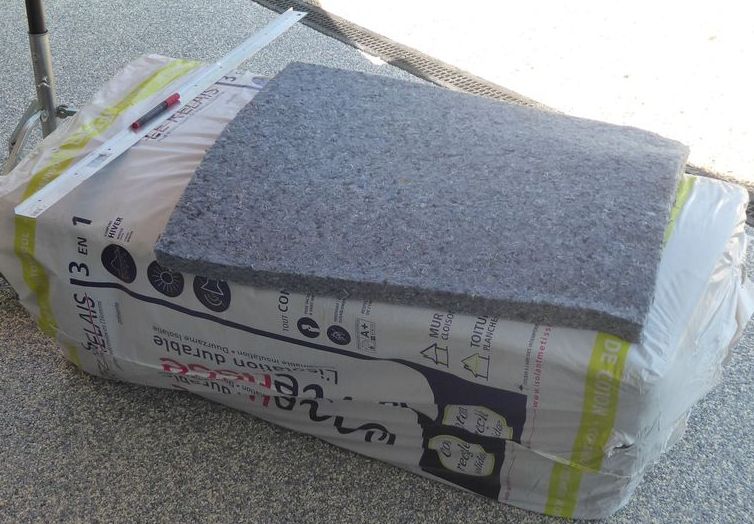

A ported box would have its internal walls lined with absorbent sheet material such as thick wool felt carpet underlay:

A sealed box would be loosely filled with absorbent material such as carded sheeps wool: https://www.woollyshepherd.co.uk/loudspeaker-wool/

A ported box would have its internal walls lined with absorbent sheet material such as thick wool felt carpet underlay:

I once made a sealed box and covered it with glass wool but I was never able to check whether or not it made a difference to the sound.

I presume you mean "filled" it with glass wool.

You may not be familiar with the "Click Test" which can be used to provide an audible indication of when the damping density in a sealed box is optimum.

Here it is courtesy of GM and planet10:

But is there something ideal to fill the box?ma caixa selada seria preenchida com material absorvente, como lã de ovelha cardada

But is there something ideal to fill the box?

I have suggested carded sheeps wool. Check out my link.

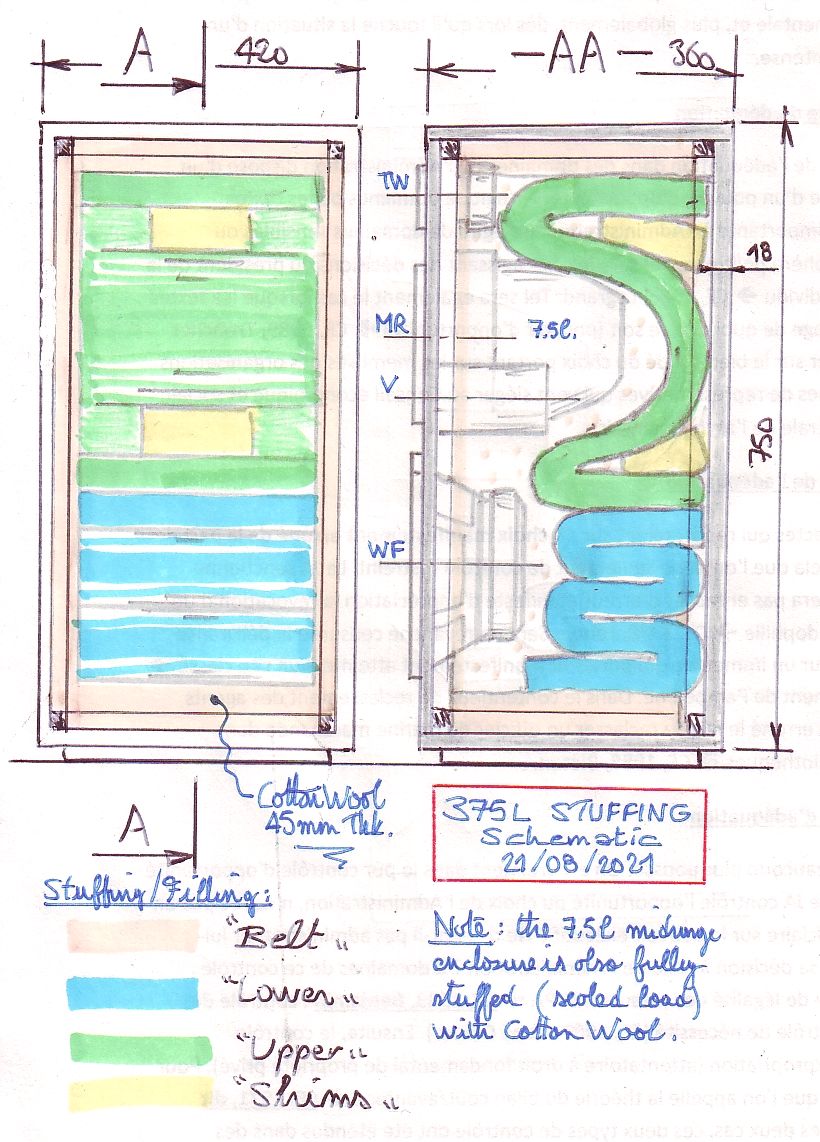

Natural fibres tend to be better absorbers of sound than synthetic fibres (such as glass fibre) because of the roughness of their surfaces.

Here's an image of wool and other natural fibres (and synthetic polyester fibre at extreme right for comparison purposes):

How much wool do I put inside the sealed box?Here's an image of wool and other natural fibres (and synthetic polyester fibre at extreme right for comparison purposes):

And because of much more varying fiber diameter.Natural fibres tend to be better absorbers of sound than synthetic fibres (such as glass fibre) because of the roughness of their surfaces.

I found open-cell melamine foam (basotect) to be very useful for "lining" ported speakers.

F

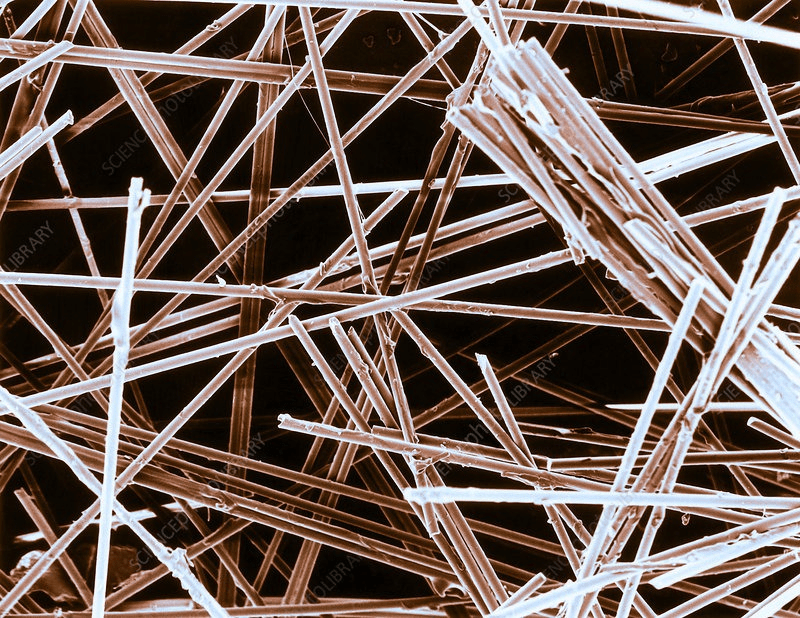

Yes, look how uniform in diameter glass fibres are:

And because of much more varying fiber diameter.

Yes, look how uniform in diameter glass fibres are:

How much wool do I put inside the sealed box?

The exact quantity of absorbent can be determined by the Click Test I mentioned in post #3.

Or you could simply fill the enclosure loosely with the wool, but only up to the point where it will come in contact with the magnet assembly of the loudspeaker driver when it is fitted.

I suspect we all have our favourites.

As Galu suggests sealed boxes are typically filled (i use acoustastuff), reflex boxes are lined. For that i like natural materials, cotton or wool felt.

Sheeps woolis is a good damping material, it tends to sag, i’d mix it 50/50 with something like acoustistuff to hold it in place.

I also tend to use felt on the walls near the driver for anythjing above the bass.

dave

As Galu suggests sealed boxes are typically filled (i use acoustastuff), reflex boxes are lined. For that i like natural materials, cotton or wool felt.

Sheeps woolis is a good damping material, it tends to sag, i’d mix it 50/50 with something like acoustistuff to hold it in place.

I also tend to use felt on the walls near the driver for anythjing above the bass.

dave

Historically, fiberglass insulation with different 'R' values based on the needs of the app.But is there something ideal to fill the box?

The exact quantity of absorbent can be determined by the Click Test I mentioned in post #3.

Or you could simply fill the enclosure loosely with the wool, but only up to the point where it will come in contact with the magnet assembly of the loudspeaker driver when it is fitted.

All the old guys I know in my town who used to mess around with old sound systems say that the best thing to put in a sealed box is the famous fiberglass wool, but they never told me why or how much...I suspect we all have our favourites.

As Galu suggests sealed boxes are typically filled (i use acoustastuff), reflex boxes are lined. For that i like natural materials, cotton or wool felt.

Sheeps woolis is a good damping material, it tends to sag, i’d mix it 50/50 with something like acoustistuff to hold it in place.

I also tend to use felt on the walls near the driver for anythjing above the bass.

dave

Forgot to add that the components should be covered with cheesecloth or similar for protection or stuff the insulation in a cheesecloth or similar bag.Historically, fiberglass insulation with different 'R' values based on the needs of the app.

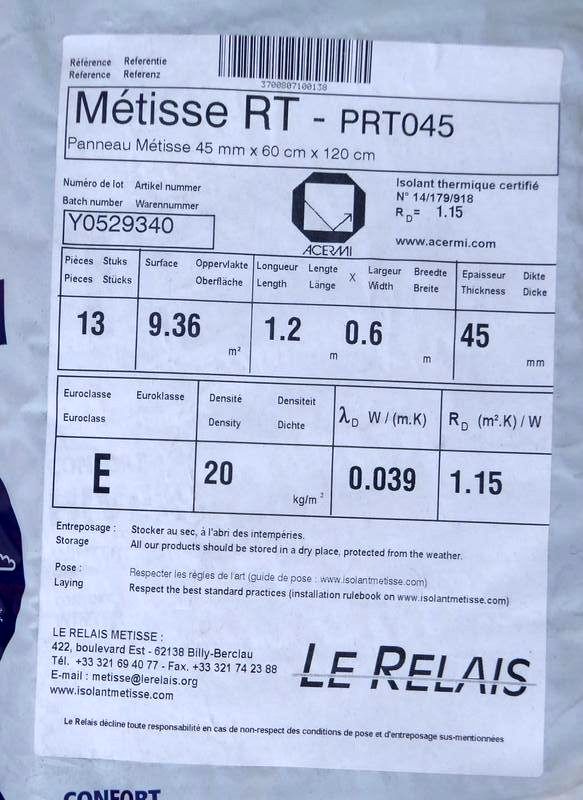

Personally; I use Cotton Wool, in Sealed or Bass-Reflex enclosures :

Historically, fiberglass insulation with different 'R' values based on the needs of the app.

Generally speaking

A sealed box would be loosely filled with absorbent material such as carded sheeps wool: https://www.woollyshepherd.co.uk/loudspeaker-wool/

A ported box would have its internal walls lined with absorbent sheet material such as thick wool felt carpet underlay:

View attachment 1307319

Do you think this test is valid?

I was thinking about using glass wool only in the sealed midrange box

Rockwool OR Fiberglass for DIY sound panels?

Last edited by a moderator:

I was thinking about using glass wool only in the sealed midrange box

Fibreglass, or indeed Rockwool, would work well in a midrange box provided you understand the variables concerned.

The degree of sound absorption of a material depends on four variables:

- The type of material

- The density of the material

- The thickness of the material

- The frequency of the sound

For example, here's how the acoustical performance of Rockwool of density 6 lb per cu ft and thickness 2" varies over the midrange frequencies:

| Frequency (Hz) | 250 | 500 | 1,000 | 2,000 |

| NRC (the bigger the better) | 0.81 | 1.06 | 1.02 | 0.99 |

Yes to natural fibers for having all that 'bonus' surface area (as this is a 'molecular gas thermodynamic process'), but no to felting it or otherwise linking it together (carding?), as it should be loose and fluffy, and located in the center of the volume, not on the walls.I have suggested carded sheeps wool. Check out my link.

Natural fibres tend to be better absorbers of sound than synthetic fibres (such as glass fibre) because of the roughness of their surfaces.

Here's an image of wool and other natural fibres (and synthetic polyester fibre at extreme right for comparison purposes):

View attachment 1307331

(carding?)

Carding involves separating and straightening sheep's wool with two brushes to create soft, fluffy wool which can later be spun into yarn.

- Home

- Design & Build

- Construction Tips

- Variations of materials for internal lining, which is the best?